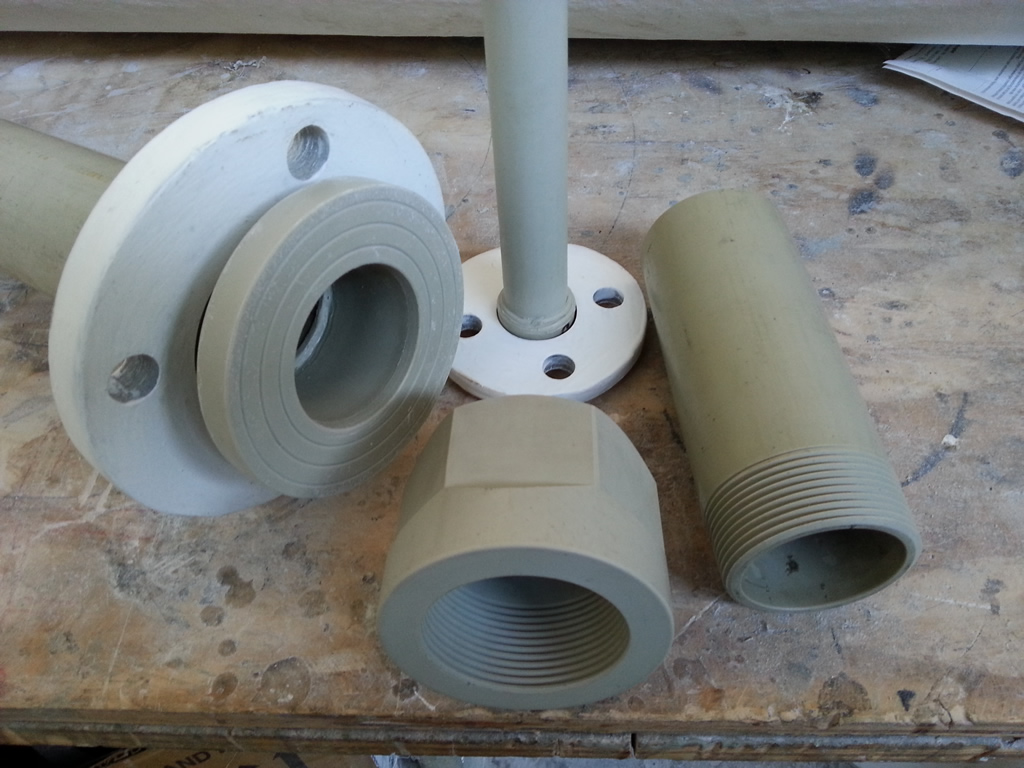

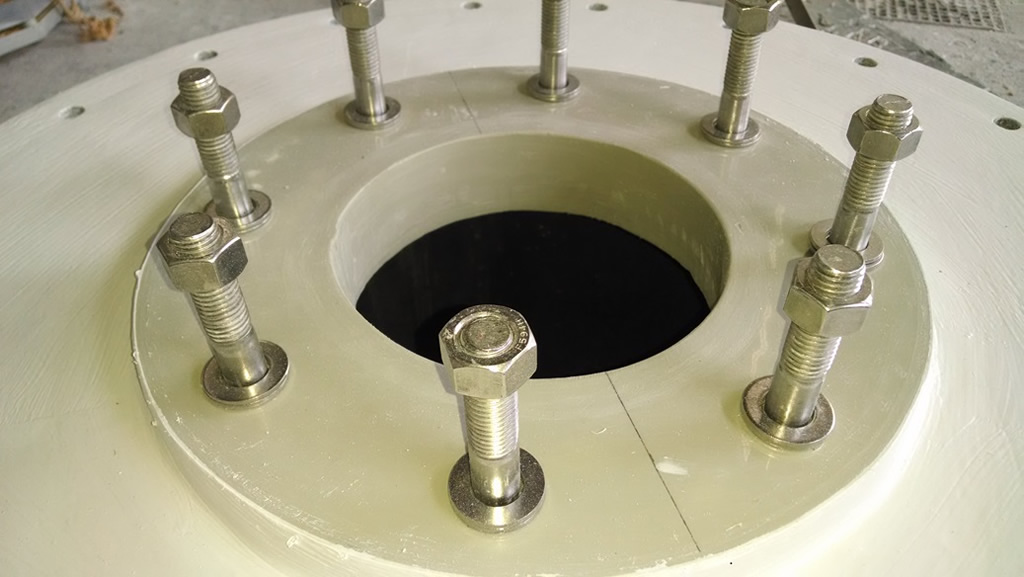

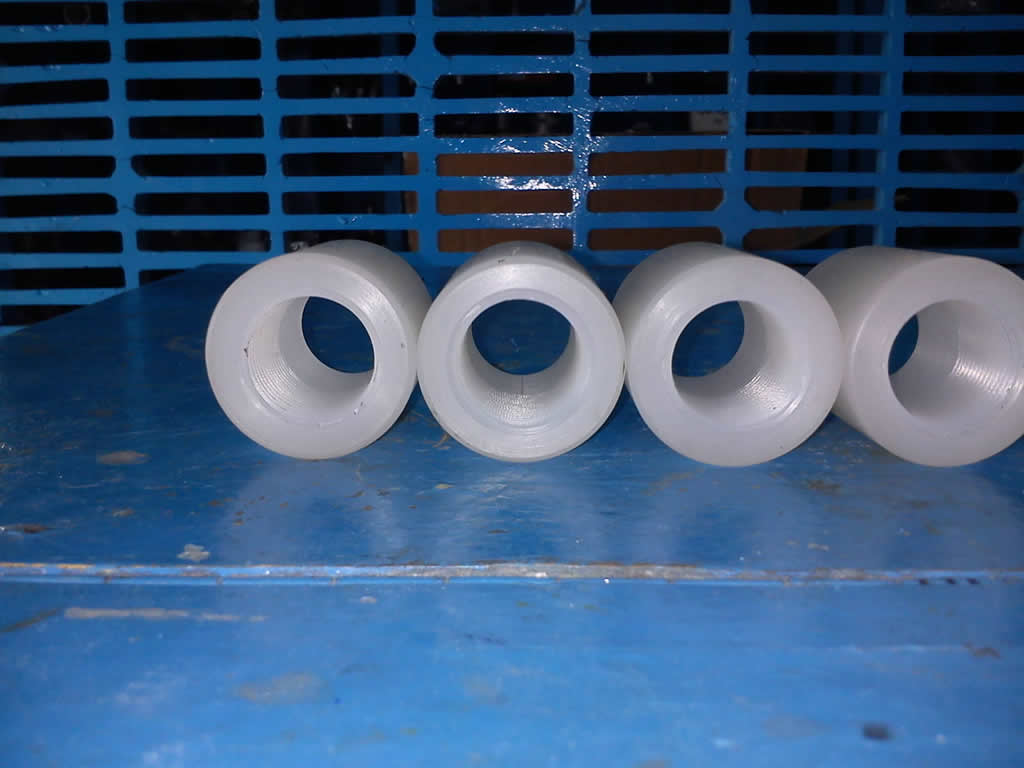

Pipes and fittings

• Description: A duct that has the function of transporting a fluid, commonly liquid, but can also be gases.

• Design ranges: The pipes and fittings to be used in a system are selected on the basis of design characteristics, such as:

a. Fluid to be handled

b. Temperature

c. Pressure

The fluid will determine the type of material to be used, guaranteeing the chemical resistance of the pipeline.

The pressure is the value of greater importance in the selection of pipes since the thickness will be selected based on this value.

In the industry it is known as CLASS and the following ranges are used:

- 25, 50, 75, 100, 125 and 150 PSI for pipes constructed with FRP, according to the NBS PS15-69.

- 150, 300, 400, 600, 900, 1500 and 2500 PSI pipes built with steel, according to ANSI B16.5

- For thermoplastics such as PE, PP, PVC, CPVC, PVDF, among others, they are known as SCHEDULE and in the industry the schedule 80 is commonly used, withstanding pressure of 150 PSI.

• Applications: Industrial plants (metallurgical, chemical, petrochemical, pharmaceutical, etc.) shopping centers, hospitals.

• Benefits:

a. The benefit of using pipelines in the industry is that they can carry fluids over long distances, as an example we can see what is done in the petrochemical industry where there are pipelines that cross oceans.

ENGLISH

ENGLISH